Common Issues for Poor Heat Exchanger Performance

In this article, we aim to identify the critical issues which may have implications on process plant performance and offer some ideas on how to overcome those problems.

Much of the time heat exchanger performance issues can be fixed with a variety of simple solutions, one being turbulators like hiTRAN® Thermal Systems. By introducing novel technologies this ensures process plants continue to maximise performance over time when handling varying process conditions. However, in some instances the most common heat exchanger problems can be a lot harder to resolve, leading to ever-increasing operating costs and high capital costs. Some of the most common heat exchanger problems for many process plants include the following;

- Vibration issues

- Exchanger leakage

- Increasing exchanger energy consumption

- Pass Partition bypassing (thermal leakage)

- Air cooler air recirculation

- Fouling.

All of the above problems can contribute to an under-performing exchanger, the main issue is determining the critical problem (or a combination) that needs to be resolved.

An audited approach to analyzing the given heat exchanger needs to be adopted, as one particular problem can be closely linked to another problem on the list; resulting in a ‘chain reaction’. For example, a lot of exchanger leakage can be found to come from flow distribution issues. If the flow through the exchanger is not uniform, then high flow velocities can cause an additional problem, vibration. This vibration can increase the effect of erosion in exchangers which then leads to frequent leakage of exchangers creating problematic maintenance and associated costs. Analytical tools as CFD services, provided by CALGAVIN®, can be used in a variety of ways to address flow distribution issues inside heat exchangers. This allows engineers to manipulate the flow via changing pressure drops through appropriate solutions offered.

An example of studies carried out at CALGAVIN are given in this webinar:

Closely linked to flow distribution problems, is high energy consumption in terms of utilities. With varying flow velocities occurring, there will be tubes or areas on the shell side where poorer heat transfer is taking place compared to other areas inside the heat exchanger. Operationally fans and pumps are usually increased in power to overcome the poor heat transfer, but such technologies as CALGAVIN’s hiTRAN® Thermal Systems greatly improve the heat transfer efficiency, benefitting a decreased demand of cooling or heating energy needed for a given duty.

Traditional engineering practices such as site visits, taking measurements and examining the exchanger in operation also play a part in determining pass partition bypassing. Infrared thermal readings can resolve an unidentified problem with a simple solution. Onsite audits can also determine air recirculation problems, taking into account the exchanger’s surrounding environment which can also have an impact, i.e. high winds, nearby exhaust gas etc.

A variety of troubleshooting topics are addressed in the following webinar series:

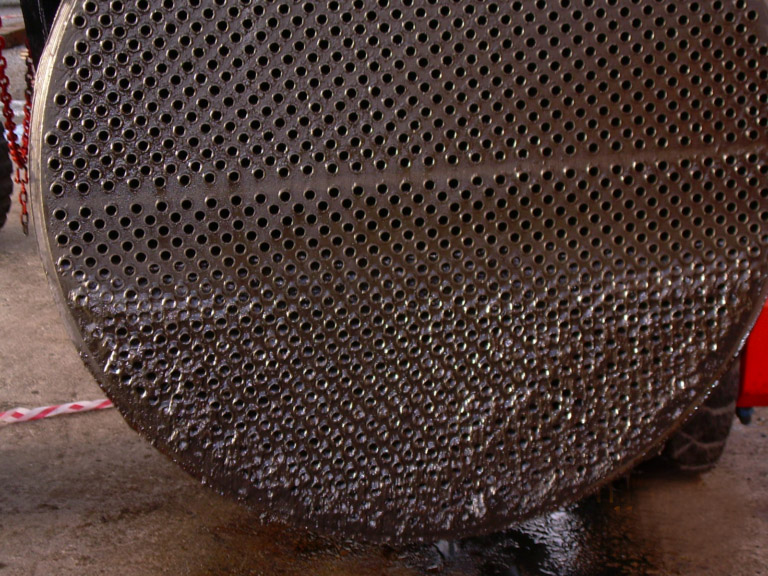

Fouling Example

Finally, the problem of fouling can come in many forms listed below, but it is essential to determine the type of fouling, and it’s a mechanism to offer a solution.

Different types of fouling can be described as the following;

- Crystallisation

- Decomposition

- Polymerisation and or oxidation

- Settlement of sludge, rust or dust particles

- Biological deposits

- Corrosion.

Fouling, in general, can be determined by either the nature of the fouling process fluid, the heat transfer process or both. Biological fouling or settlement of particulate can usually be rectified by making appropriate low-cost process change to slow down the impact of these types of fouling. Improved filtration of water is usually associated with biological fouling before the exchanger, greatly improving operational performance. Again, further filtration processes can be implemented upstream of the exchanger to remove particulate from process streams as well.

However, a substantial mechanism for many types of fouling is heat transfer. For crystallization, decomposition and polymerisation, heat transfer plays a part in the rate of fouling that occurs. For polymerisation or decomposition, high temperatures increase the rate of fouling occurring. By decreasing the temperatures this will obviously slow down this rate and therefore in some cases reduce the frequency of cleaning. This applies to also crystallization, where low temperatures drive the fouling so therefore maintaining higher surface temperature can impair the effect.

CALGAVIN's team use heat transfer enhancement technologies to improve the heat transfer, therefore positively changing the temperatures needed to process a duty in the direction where fouling can be mitigated through large increases in heat transfer efficiency.

At CALGAVIN when adopting the use of our primary product hiTRAN, questions are asked upon the influence of fouling and any effects that occur because of changed flow conditions inside exchanger tubes.

An in depth webinar looks into this phenomenon and how fouling is affected?

There are many other common heat exchanger problems which can be very specific to any given process plant or heat exchanger variety; some of the problems might only occur within one plant due to the type of fluid being processed.

Our heat transfer engineers have extensive knowledge of thermodynamics, heat transfer and fluid flow, combined with the experience of providing solutions to hundreds of plants and engineering teams worldwide.

Speak to us now!